This software is a secondary development software based on SolidWorks, which is used for pipe cutting. The installation is convenient. It is embedded in SolidWorks as a plug-in and easy to use. The following are the features and advantages of the software:

This software is for intersecting line calculation, nesting and cutting of common pipe. This software has powerful functions, and it is easy to use. Users only need to import the finished parts. The software can calculate the cutting line automatically according to the parts imported by the user. The function of automatic nesting enables you to cut a whole steel pipe into multiple sections at one time without manual intervention. The steel pipe cutting is as convenient and fast as steel plate cutting. And the automatic layout realizes the optimized use of raw materials, which greatly saves materials as well as reduces the cutting time and improves the efficiency of the cutting machine.

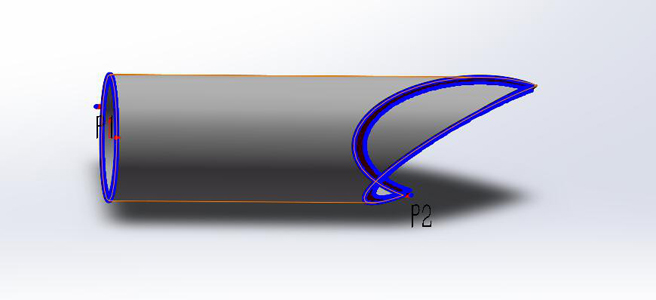

This software can generate and cut the following types of pipe cutting node:

The normal version supports vertical and inclined pipe cutting, while the professional version supports the functions of square pipe, round pipe groove and channel steel cutting. Holes of various shapes are opened on the pipe. The software can automatically identify the drawn holes, as long as the holes are made under solidworks.

This software supports edit function of the addition of inlead, cutting compensation, spacing between parts, common edge of track, manual nesting, and generating track.

After the end of the nesting, the software can directly display the nesting results, users can see the results clearly.

This software has the function of dynamic simulation cutting, and can dynamically simulate cutting of the nesting result. Users can see the cutting result directly.

In this software, users can maintain raw material data by themselves, and the raw material results after the end of the nesting can be synchronized to the raw material database for the next cutting.

This software can automatically generate G code file.

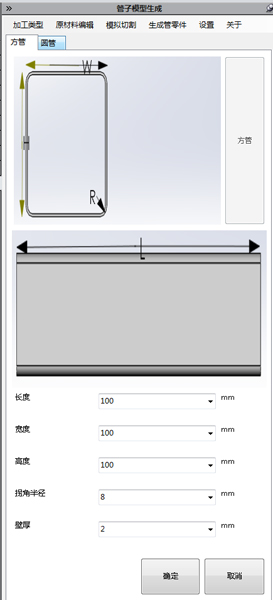

This software can automatically generate the original parts of the pipe by inputting the parameters.

This software can return the specific G code file back to generate graphics.

The software expandability is strong. This software is a completely independent intellectual property product. Our company has all the core technology and source code of this software. If the user has special requirements, we can customize the development according to the user's requirements.

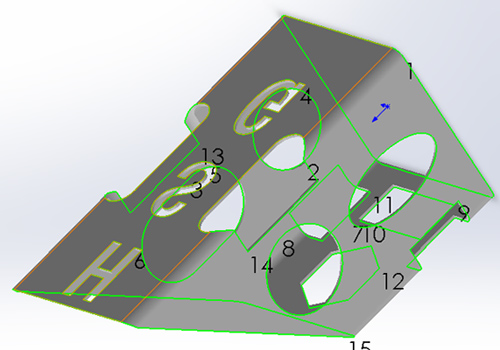

1. modules: Graphic import function

Function Description: it can directly import the file(SLDPRT) of SolidWorks, the normal version can automatically recognize the square pipe, track of circular pipe. While the professional version can recognize the channel, square pipe, circular pipe groove, track lines to be highlighted.

|

|

|

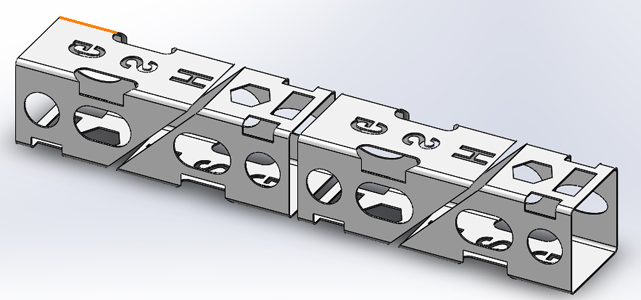

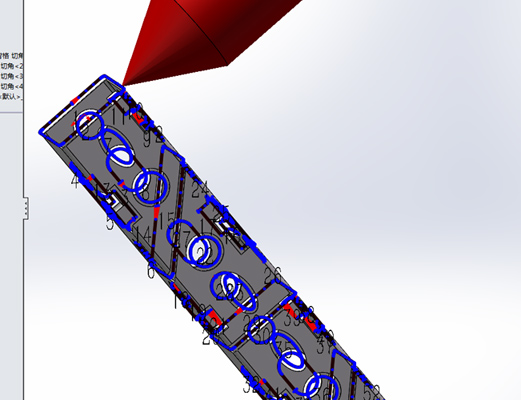

2 modules: nesting function

Function Description: For the same specification parts can be nest at the same time.

Also can follow the import order to manually nest for the most economical way.

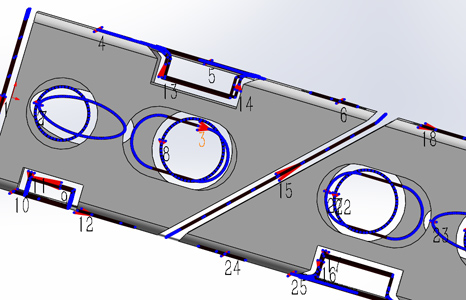

Nesting results can be displayed in the interface. The starting arc point, cutting trajectory, trajectory labels can be displayed at same time.

3、 modules: process parameter function

Function Description: It can realize to share common edges when nesting, cutting compensation, the addition of lead-in, whether the trajectory is cut by plane or by the distance from the origin, the distance between parts when nesting, whether the cutting gun rotate in advance, whether the trajectory need to be deleted manually, Whether the parts need to layout manually (the clamp may affect the leftover material may only the long pipe) and whether the trajectory prevents interference etc.;

4 modules: (1) groove function

Function Description: It can groove on square pipe and circular pipe. To realize the dynamic groove and the fixed groove. The middle holes are fixed groove, and users do not need to rework.

(2) Dynamic Simulation

Function Description: Dynamic simulation results are available. Parts and the cutting gun can be for animation demonstration.

(3) model of automatic generation

Function Description: The input parameters in SolidWorks can directly generate the original parts model.

(4) G code return function

Function Description: It can draw out the G code file by importing G code files. Draw with lines which supports square pipe and circular pipe.

(5) material library and remanent material library

Function Description: It has the management function of material library and remanent material library. The remanent material can be stored in the raw material library directly after nesting.

(6) G code collocation arbitrarily

Function Description: Any combination of G code file, two axes, four axes, five axes, etc., adjustable working direction, and the adjusted cutter point can be set.