Software description

This software is used for CNC glass engraving machine. Its function is to generate the processing code which can be recognized by the CNC glass engraving machine from the design drawing of glass engraving by the user.

The software can automatically or manually connect segments with similar angles at the end points into a whole.

Software can easily set parameters of sharp angles of all lines, closed form, speed etc.. Simple graphics can be processed from opening graphics to output G code in a very short time.

Display graphical path. After the setting is completed, the software will display the processed graphics and path directions.

Convenient and fast path setting, and users can set the direction of any line and other internal parameters.

Easy to learn and fast to use. Users can operate the software without special training or just need simple training because of the simplicity of the setup and operation.

Software operating environment

Hardware requirements

IBM PC compatible machine

INTEL or AMD 1GHz to CPU

More than 1GB of memory

More than 1GB of free hard-disk space

The standard keyboard and mouse

Software requirements

Operating system of Windows XP, WIN7, WIN8

.netframework 3.5 runtime environment

Complete installation of the font library

The software function

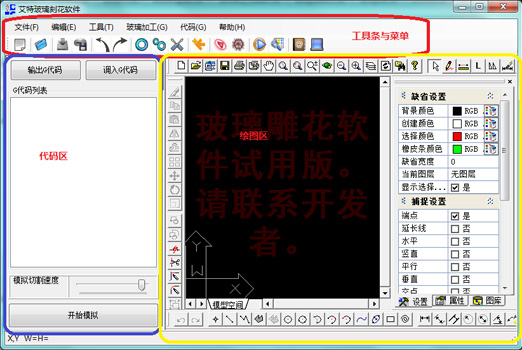

The main interface of software

The main software interface as shown below:

From here you can see that the software is divided into the following functions:

1, the right for the drawing area

2, left for the code browser

3 above for the toolbar and menu (toolbar and menu function repetitive and alternate)

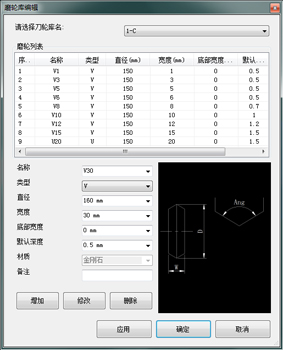

The grinding wheel library settings

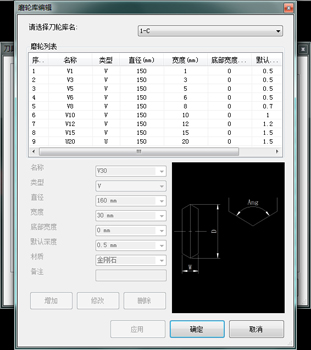

The grinding wheel library settings as show below:

This software can set three grinding wheel library. The user can choose to edit the name of the grinding wheel library. As shown below:

After the user selects the name of the grinding wheel library, the list of grinding wheels can be edited.

The user can add, modify and delete the grinding wheel library. The situation of the grinding wheel library should be consistent with the actual grinding wheel situation of the user's warehouse, so that it can be used in the future.

The edited form will be saved to the hard disk after the user click the “application” when the user has finished to compile the grinding wheel library. Click “OK” to save and exit the current form. Click “Cancel” to exit without saving form.

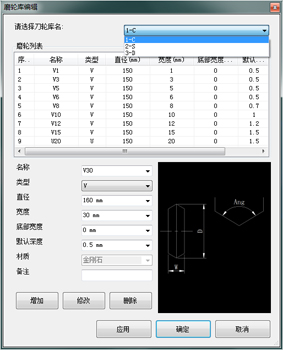

The cutter tool library settings

The cutter tool library settings as shown below:

The user can edit the cutter tool number from T1 to T10. When the user selects the vajra wheel, the tool can only be selected from the grinding wheel library. The user can input the diameter and width of the wheel freely if choose the polishing wheel and split the resin wheel.

The user can adjust the corresponding data from the grinding wheel repository to the current tool when click the button of "select from the grinding wheel library" list. As shown below:

The user selects the options in the grinding wheel library and then clicks “ok”.